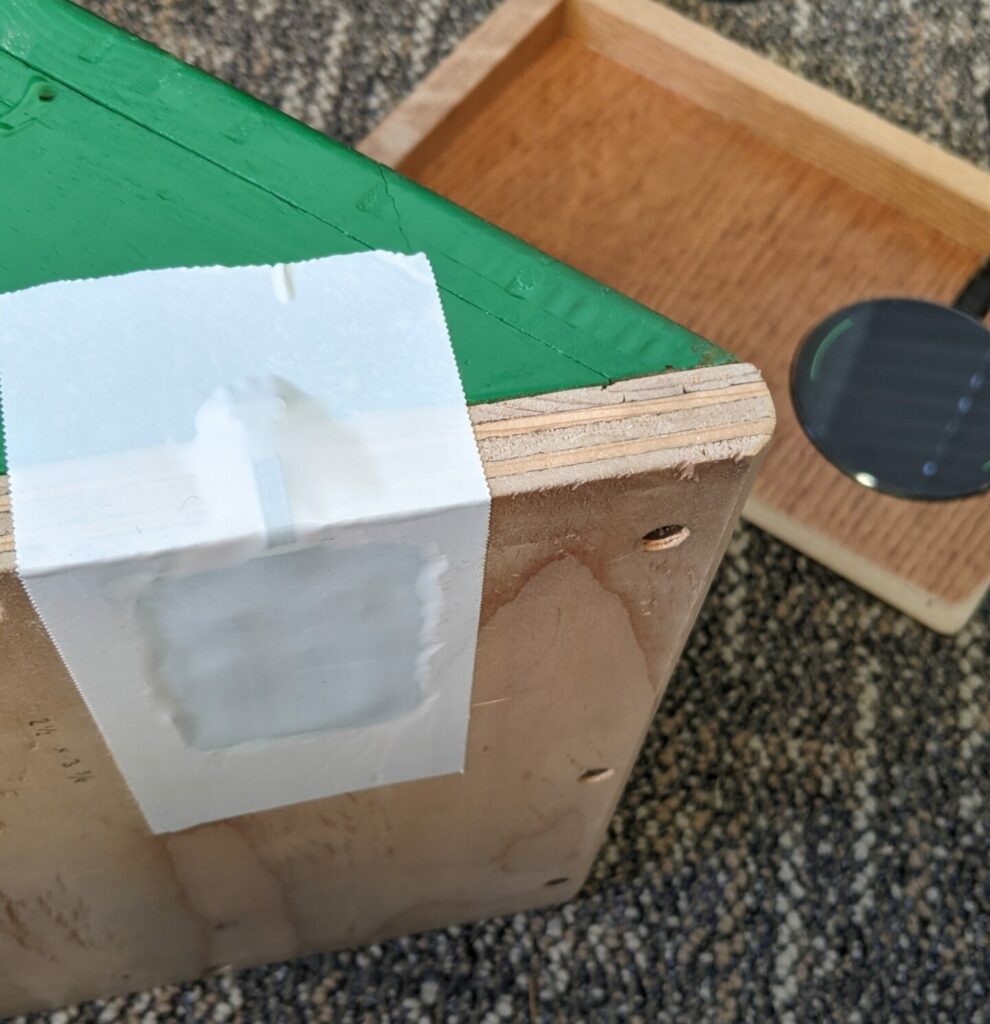

In preparation for the October 14, 2023 Annular Eclipse, I wanted to use my binoculars to get a close look at the sun during the eclipse. I could buy premade solar filter lens caps at $50 a piece, that may or may not fit my binoculars. Or I could buy a sheet of solar filter material for $12 and 3D print lens holders that are the perfect size.

For simple shapes, I found that using OpenSCAD is quicker, especially when making the model adjustable with parameters. I also posted this design on printables.com (https://www.printables.com/model/593894-binocular-lens-holder-with-openscad)